Stabilisation Props

Push-Pull Props

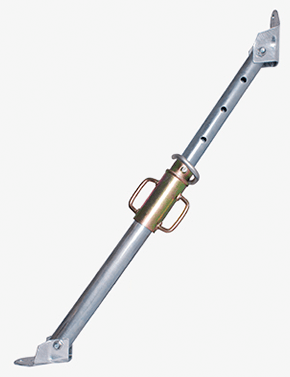

They are also known by the name “stabilization props,” and they work by pulling and pushing the formworks into place when they are laid out on the site.

ABOUT

These push-pull diagonal props consist of two telescopically slidable pipes. A threaded ring nut and a pin fitted into the slots of the inner pipe